Optimization: the key to efficient heating

Optimizing the operation of a boiler has the potential to increase the efficiency of the equipment, thereby potentially reducing energy costs and GHG emissions, as well as significantly prolonging the life of the boiler.

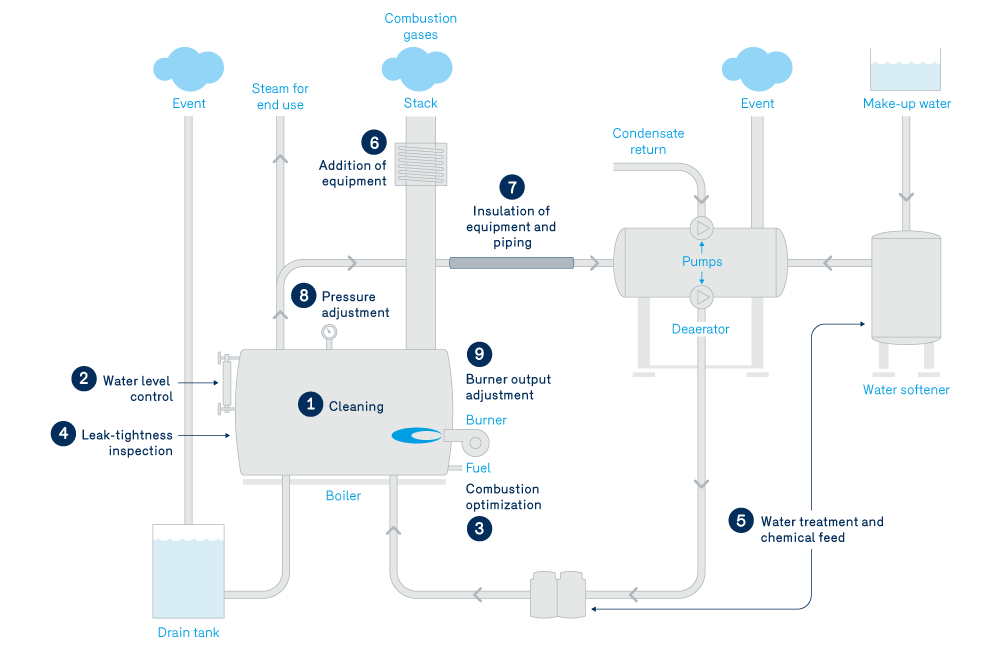

9 strategies to optimize operation

- 1

Regular cleaning of the tubes and heating surfaces :

to remove deposits that interfere with heat transfer.

- 2

Water level control :

an unstable level can affect the efficiency of the boiler and damage some components.

- 3

Optimization of combustion :

to minimize stack heat loss (addition of an O2 sensor or micromodulation system).

- 4

Leak check :

to prevent or stop steam loss at the boiler.

- 5

Water treatment :

to reduce minerals and limit purges, reducing energy and chemical consumption.

- 6

Addition of equipment :

(e.g., standard or condensing economizer) to improve boiler system efficiency.

- 7

Insulation of equipment, accessories and piping :

to minimize heat loss.

- 8

Pressure adjustment :

within the recommended range (often between 1 and 2 bar).

- 9

Burner power adjustment :

according to the actual needs of the building (with a two-stage or modulating burner, for example).

9 strategies to optimize boiler operation

8 à 12%

That’s what you can save on average in energy costs1 by regularly servicing your boiler.

Other examples of strategies that may result in cost savings are:

Installing an economizer

The economizer recovers waste heat from the exhaust gases to preheat the water, increasing system efficiency by 85% or more and reducing heat loss.

Installing a micromodulation system

This allows the burner to fine-tune its power to actual demand, reducing on/off cycles and generating energy savings of about 3%.2

Installing an O₂ sensor

The sensor continuously optimizes the air/gas ratio for more accurate combustion, reducing waste and providing savings that range from 0.5% to 2%.2, 3

Thermal insulation

This reduces heat loss from hot pipes and surfaces, improving system efficiency and providing approximately 0.5% in energy savings.4

Subvention

Énergir offers two types of grants: one for the addition of equipment and the insulation of equipment, accessories and piping (Optimizing Boiler Systems program) and one for the verification and repair/replacement of drains and insulation (Steam Trap Maintenance program). Certain conditions apply.

Boiler system optimization

Receive up to $340,000 in grants per boiler

Steam trap maintenance

Up to $106,700 per maintenance. For conditions and eligibility criteria.

Your action plan to optimize your boiler:

Hire an Énergir partner, a specialist licensed by the Régie du bâtiment du Québec (RBQ) and a member of the Corporation des maîtres mécaniciens en tuyauterie du Québec (CMMTQ). Any heating technician or contractor working on a natural gas appliance must hold a certificate of qualification in natural gas from Emploi-Québec.

A qualified partner will provide you with information on grants and on the best strategy.

Want to talk to our team?

Go further

Read this article to learn more about optimizing commercial and industrial boilers :

Legal notices

- Source : https://pro.engie.fr/economies-d-energie/comment-faire-des-economies-d-energie/tous-nos-ecogestes-travaux/entretenez-regulierement-votre-chaudiere (opens in new tab)

- Source : Centre des technologies du gaz naturel, Programme d’efficacité énergétique – Mesures de contrôle, Rapport final v.3.

- Source : Installation of an O2 sensor requires installation of a micromodulation system.

- Source : The reductions in energy consumption shown in this list are cumulative, with a maximum potential of 4%–5.5%.