Optimizing a steam system-often the backbone of heating systems in institutional, industrial and heritage buildings-relies not only on equipment performance, but also on the care with which it is maintained.

To avoid waste while making your steam system more reliable, you can:

- Have the system and steam traps inspected annually to identify leaks and repair or replace them.

- Install an automatic monitoring system on your steam traps, especially those that are hard to access.

- Insulate steam traps to reduce heat loss. Note that not all types of steam traps can be insulated (thermostatic and thermodynamic steam traps can malfunction if they are insulated). It is therefore important to find out what type of steam trap you have before insulating it.

Putting a preventive maintenance and regular monitoring program in place for your steam traps does more than address failures—it becomes a powerful energy optimization strategy. By safeguarding the performance of these key components, you improve the overall cost-effectiveness of your system and extend the service life of your facilities.

These measures offer a number of benefits, including:

- A potential reduction in your system’s natural gas consumption—and the associated GHG emissions (while maintaining the same consumption habits);

- Lower repair costs and fewer emergency interventions ;

- Increased efficiency and reliability of your steam system and the processes that depend on it ;

- Reduced safety risks for both staff and equipment.

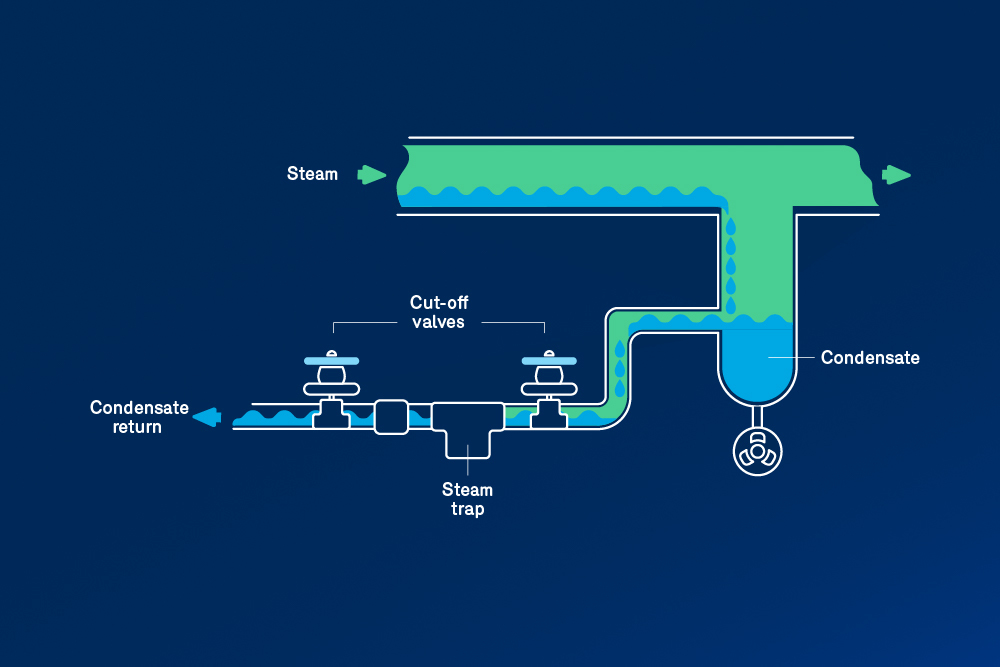

How a steam trap works

Between 15% and 25%

This is the percentage of steam traps that fail each year, resulting in leaks and overproduction of steam, which can be costly. In addition, a lack of maintenance of this equipment can, over time, cause irreversible damage to the system (corrosion, water hammer, mechanical overload), jeopardizing both the safety and durability of the facilities.

In addition to preventing steam loss, consider optimizing the efficiency of your boiler to maximize the energy efficiency of your steam system!

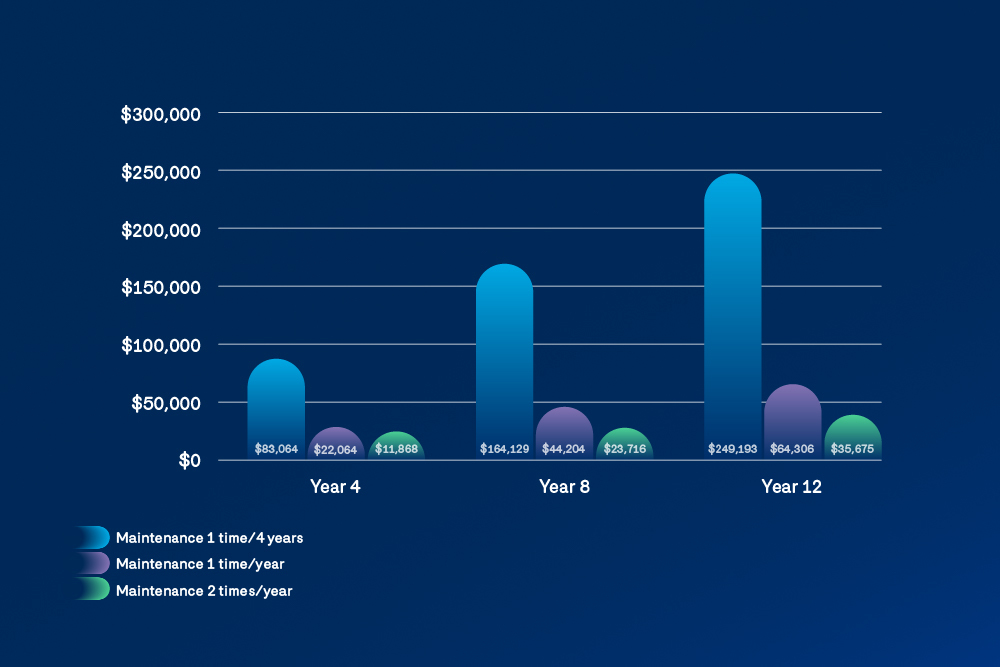

Cumulative financial losses due to steam leaks over 12 years

A medium-sized building consuming about 100,000 m3 of natural gas per year with a system of 320 steam traps could save $200,000 over a period of 12 years1 by having an annual inspection instead of one every four years, assuming consumption habits remain unchanged.1

Grants

Énergir offers grants2 for inspecting your steam system, replacing or repairing defective steam traps, installing an automatic monitoring system, and installing removable insulation covers through the Steam Trap Maintenance program.

Steam trap maintenance

Up to $106,700 per maintenance. For conditions and eligibility criteria.

Boiler system optimization

Receive up to $340,000 in grants per boiler

Take action!

- Choose one of Énergir’s authorized suppliers for your project.

- Apply for your grant before work begins.

Want to talk to our team?

Go further

Learn all about steam traps and their maintenance.

Legal notices

- Source: Énergir, Guide de sensibilisation – Entretien des purgeurs de vapeur, p. 32. (opens in new tab)

- Certain conditions apply. Grants subject to change without notice. Check each grant’s webpage for eligibility criteria.