Heat recovery allows the reuse of energy that would otherwise be lost to reduce energy consumption, operating costs and greenhouse gas emissions from buildings or processes.

This is essential to improving the energy performance of a building or industrial process.

Don’t waste, reuse: A smart solution for saving energy.

What is heat recovery?

Heat recovery is the capture of a portion of the heat released from a cooling, heating or incineration process—often referred to as lethal heat. This energy, already produced and paid for, can then be reused to preheat air, water or another process, contributing to more efficient energy management. This is essential to improving the energy performance of a building or industrial process

Concrete applications

- Multi-unit, commercial or agricultural buildings : A heat recovery ventilator (HRV) preheats new air using heat from exhaust air, improving comfort and energy efficiency.

- Factories and power plants : Stack, water or ventilation exchangers recover heat from processes to heat offices or preheat boiler make-up water.

- Data centres, hospitals and large tertiary sites : Heat from cooling systems can be recovered to heat buildings, greenhouses or an urban heating network.

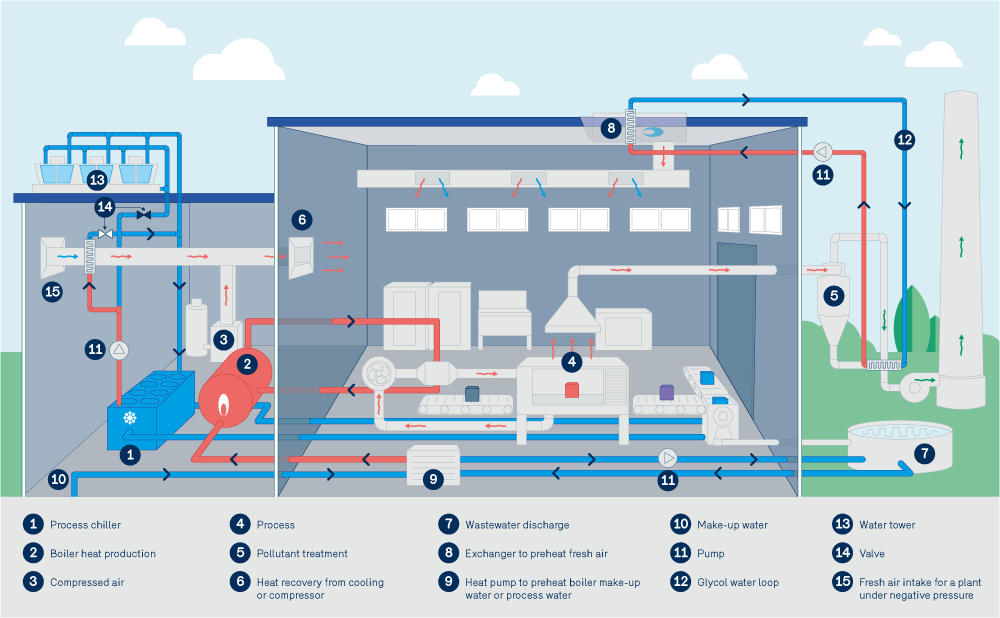

Generic diagram showing potential for heat recovery in a process plant

Recovering and putting Quebec’s industrial waste heat to use could reduce emissions by 15.8 million tonnes of CO2 [heat recovery] & equivalent—about 18% of the province’s total annual emissions1.

“We chose heat recovery because of its technical and operational advantages, but also because it gave us access to grants that allowed us to significantly reduce the return on investment period.”

Jean-Nicolas Turcotte

Senior Maintenance and Engineering Manager at Lassonde’s Saint-Damase site

Usine Lassonde

Heat recovery helped the Lassonde plant in Saint-Damase save about 80,000 m³ of natural gas in the first year.

“This process saves us a lot of water and, therefore, a lot of energy, since we don’t have to heat the water for every batch of products to be sterilized.”

Marc-Olivier Pouliot

Marketing director of Station agro-biotech

Station agro-biotech

Find out how a heat recovery autoclave allowed the company to offer a unique product while saving more than $58,000 on its energy bill.

Good to know

Heat recovery efficiency—the proportion of heat recovered—varies from 40% to 90%2 depending on the equipment selected and the specific application.

Grants

Énergir offers business customers a grant3 for waste heat recovery projects as part of its program for the implementation of energy efficient measures.

Implementation of efficient measures

You could get up to $1M in grants(up to $1/m3 of natural gas saved)

Your heat recovery project action plan

- Choose a consulting engineering firm. Tell them you’re interested in Énergir grants so they can assist you in the process and take care of the grant application (before work begins).

- Take action. Kick off your project and enjoy the energy savings in the first few months.

Want to talk to our team?

Legal notice

- Source : Presentation by Transition énergétique Québec and Innovagro Consultants (opens in new tab)

- Source : For more information on the methodology used to calculate greenhouse gas (GHG) emissions reduction data associated with the use of fossil natural gas, see our methodology page. (opens in new tab)

- Certain conditions apply. Grants subject to change without notice Check each grant’s webpage for eligibility criteria.